Internal anti-corrosion coatings

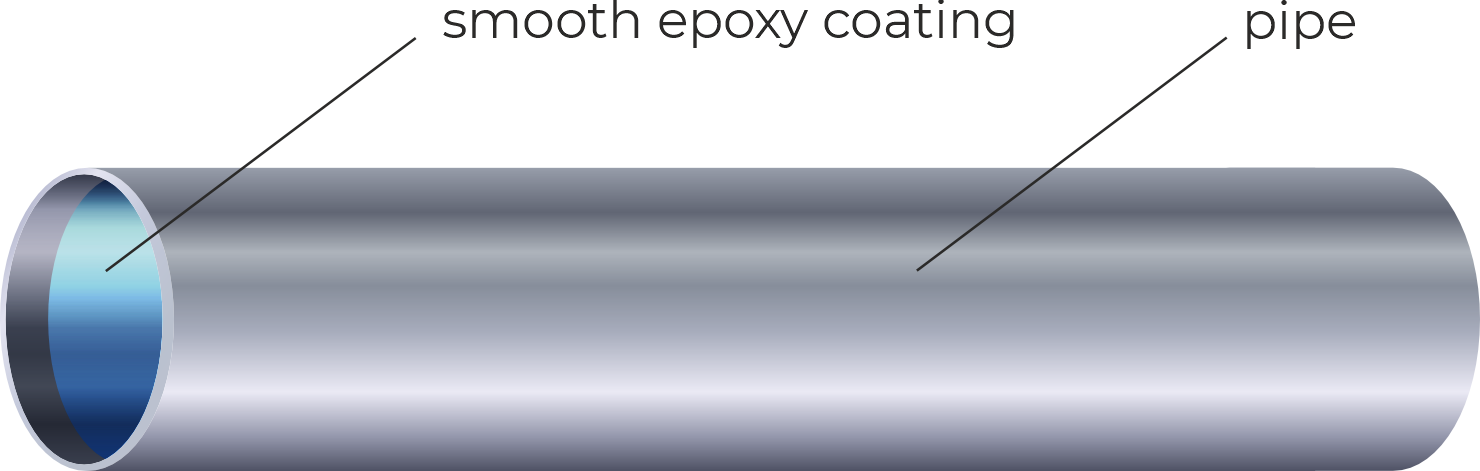

Internal smooth epoxy coating (40-150 microns)

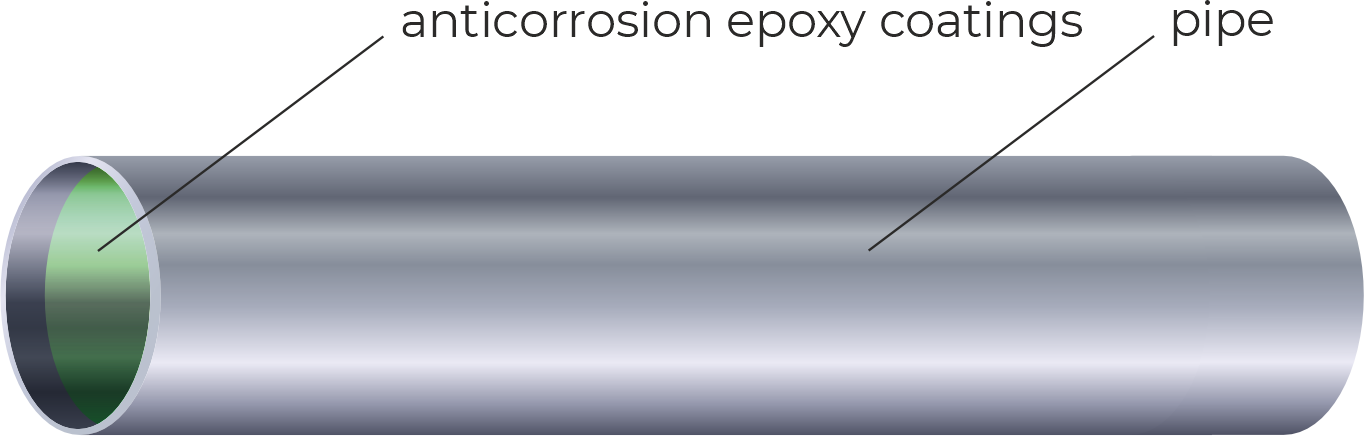

Internal anti-corrosion coating (200-1000 microns)

Coatings of this type are a type of smooth epoxy coatings designed to be applied to the inner surface of pipes in the factory to increase their throughput capacity and reduce transportation costs. They are intended for use in main gas and oil pipelines.

Internal smooth epoxy coating (40-150 microns)

The internal smooth epoxy coating of 40-150 microns from UKRTRUBOIZOL allows increasing the volume of pumping of pipeline contents by up to 10-15%, as well as reducing the cost of purchasing pipes by reducing the diameter of pipes, their wall thickness and reducing the operating pressure of the pipeline.

In addition, this type of pipe with an internal coating has anti-corrosion properties – a smooth epoxy coating protects the inner surface of pipes during storage and transportation from destruction as a result of interaction with the environment, preventing the occurrence of bacteriological corrosion. This coating, due to its almost mirror-like surface, reduces the cost of internal pipe cleaning during pipeline operation.

Technical specifications

The main advantage of using a smooth coating is that it reduces the friction of the working medium against the wall, thus reducing the cost of transporting the medium, as well as the cost of transporting the medium:

Anti-corrosion epoxy coatings are applied in the factory to the inner surface of pipes to protect the pipe from internal corrosion, which in aggressive environments can reach 1 mm (pipe wall thickness) or more in a month.

Internal anti-corrosion epoxy coating (200-1000 microns)

Anti-corrosion epoxy coatings by UKRTRUBOIZOL protect industrial pipelines, oil and water pipelines during operation, as well as during storage and transportation of pipes.

Additionally, UKRTRUBOZOL anticorrosive epoxy coatings have an almost mirror-like surface and are highly smooth, which, in addition to their anticorrosive properties, also gives them the properties of smooth coatings, increasing the pipeline capacity, reducing the amount of deposits on the inner surface of the pipe, and reducing the cost of in-pipe cleaning during pipeline construction.

When used for water pipelines, it improves water quality and reduces pipeline fouling.

Properties and advantages of UKRTRUBOIZOL anti-corrosion epoxy coatings:

ANTI-CORROSION INSULATION OF STEEL PIPES

Products of UKTRUBOIZOL

Highly reinforced insulation of steel pipes - a wide range of coatings for long-term (up to 50 years) pipe protection: external anti-corrosion (2-layer and 3-layer based on extruded polyethylene and polypropylene); internal (smooth and anti-corrosion, epoxy and polyurethane);