Highly enhanced insulation of steel pipes

Highly enhanced insulation of steel pipes – a wide range of coatings for long-term protection of pipes (up to 50 years).

Highly enhanced insulation of steel pipes is required when laying underground, above-ground and underwater oil, gas and water pipelines. The well-protected metal resists pressure and temperature drops, friction and mechanical stress. Steel is protected against rust and fungus by coating the outer and, if necessary, the inner surface of pipes with specially developed polymer coatings.

This coating provides reliable and long-lasting (up to 50 years) corrosion protection for underground and subsea oil, gas, and water pipelines with high operating temperatures (up to 140 °C) in conditions of hard-to-reach pipelines (underwater, under roads, etc.), high mechanical loads, corrosive soils, soils with stray currents, etc.

The coating is also used for directional drilling and crossing roads and rivers.

The unique technological process of Ukrtruboizol ensures the production of a PE coating with an almost monolithic structure that cannot be delaminated or removed from the pipe without the use of cutting equipment.

Due to the high strength of polyethylene and high adhesion, the coating is practically not damaged during construction and installation work and transportation, which greatly simplifies and shortens the construction and installation period.

Due to the high inertness of polyethylene, the coating does not absorb moisture and does not break down under the influence of salts, groundwater, soil electrolytes, etc.

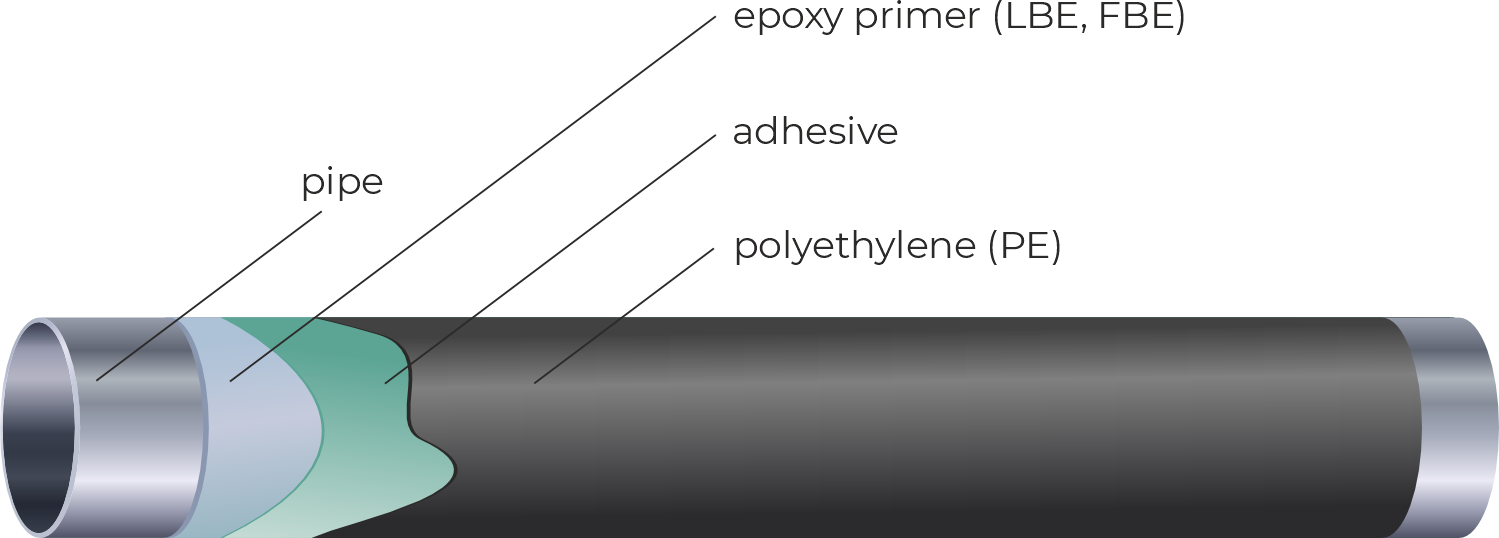

External anti-corrosion coating based on extruded polyethylene 3PE 2 PE

3PE insulation

3-layer outer anti-corrosion coating based on extruded polyethylene (3РЕ)

Highly reliable protective coating consisting of a layer of epoxy primer, polymer adhesive and a layer of polyethylene.

Properties and advantages of 3-layer coatings based on polyethylene Ukrtruboizol

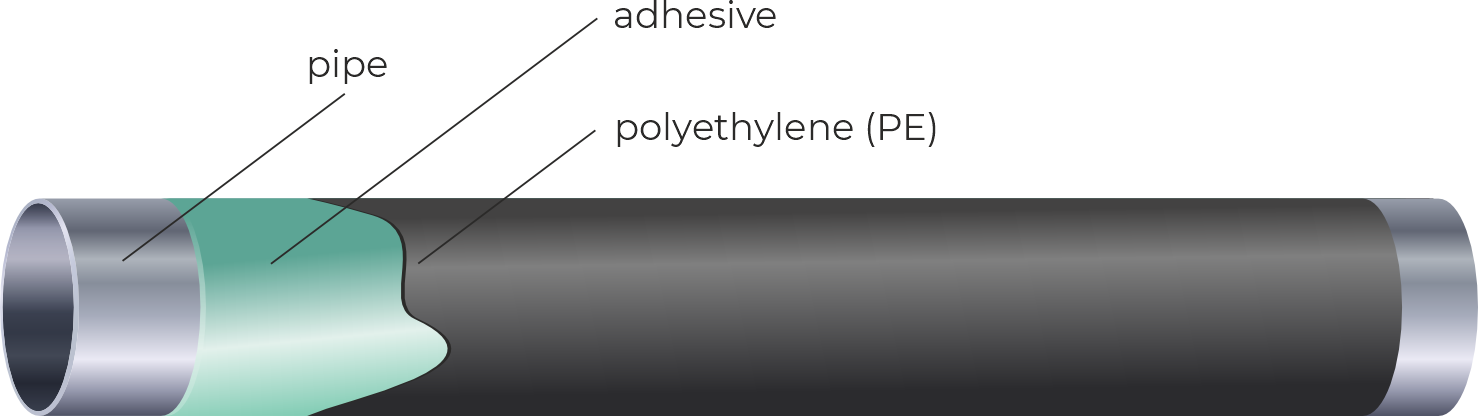

2PE insulation

2-layer external anti-corrosion coating based on extruded polyethylene (3PE)

A 2-layer coating based on extruded polyethylene provides reliable and long-term (up to 50 years) corrosion protection for underground oil, gas and water pipelines in conditions of corrosive soils, soils with stray currents, etc.

2-layer insulation consists of similar components as 3-layer insulation, but it lacks the first layer of insulation, namely, an epoxy primer.

Consists of:

Properties and advantages of 2-layer coatings based on polyethylene Ukrtruboizol

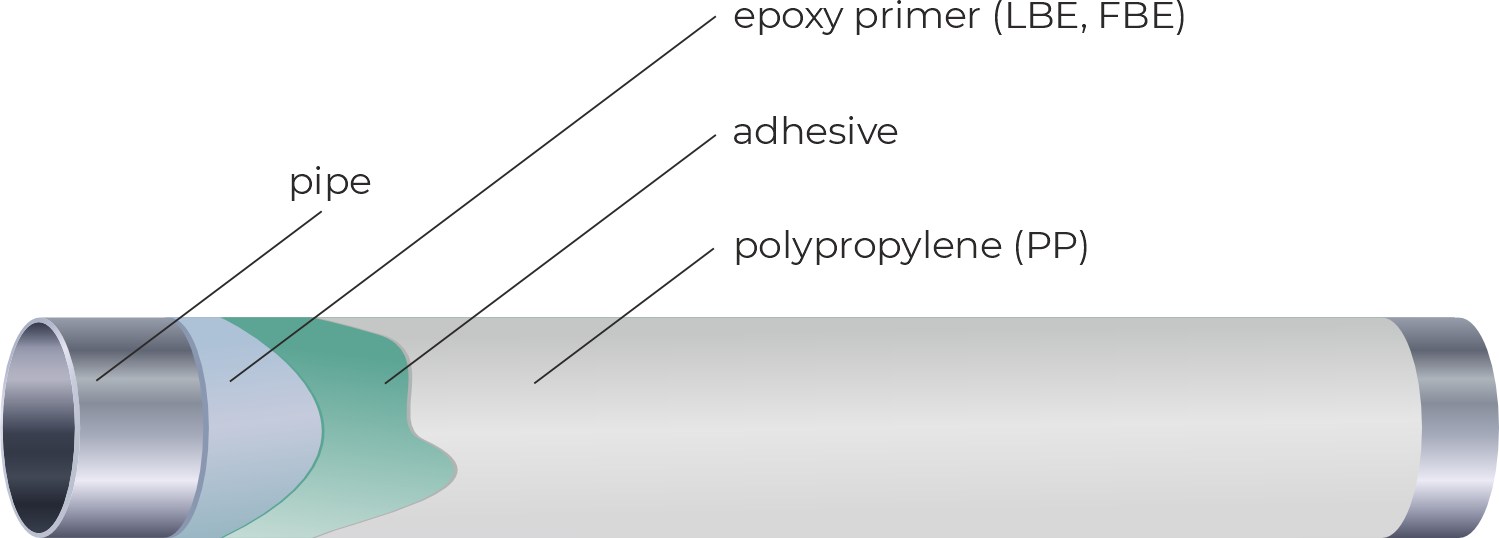

External anti-corrosion coating based on extruded polypropylene 3PP

3-layer external anti-corrosion coating based on extruded polypropylene (3PP) is a highly reliable protective coating consisting of an epoxy primer layer, a polymer adhesive and a polypropylene layer.

Extruded polypropylene coatings have increased mechanical strength. Pipes with this coating are recommended for the construction of pipelines using both open and closed laying methods (puncture and borehole methods).

Technical characteristics:

Pipe diameter: 32-1422 mm.

Note:

The technical characteristics of the coating are regulated by the manufacturer’s specifications or customer requirements.

3PP insulation

3-layer outer anti-corrosion coating based on extruded polypropylene (3РР)

Highly reliable protective coating consisting of a layer of epoxy primer, polymer adhesive and a layer of polypropylene.

Properties and advantages of 3-layer coatings based on polypropylene Ukrtruboizol

ANTI-CORROSION INSULATION OF STEEL PIPES

Products of UKRTRUBOIZOL

Highly enhanced insulation of steel pipes – a wide range of coatings for long-term (up to 50 years) pipe protection: external anti-corrosion (2-layer and 3-layer based on extruded polyethylene and polypropylene); internal (smooth and anti-corrosion, epoxy and polyurethane);