Thermally insulated products UKRTRUBOIZOL

This work was carried out as part of the implementation of the “Single Pipe Center” strategy. It consists of meeting as many customer needs as possible related to the word “pipe” and concentrating production capabilities: large-diameter steel pipes, external and internal coatings, joint insulation materials, repair structures for main product pipelines, polyethylene pipes, pre-insulated pipes and fittings, etc.

The integration of the new production with existing technological processes has made it possible to take full advantage of the following benefits:

One of the key indicators of the performance properties of rigid polyurethane foam (PUF) used as thermal insulation for pre-insulated pipelines is the thermal conductivity coefficient. Its value depends both on the nature and characteristics of the foaming agents and on the technological features of the PUF production process.

According to the requirements of the Ukrainian national standard DSTU B V.2.5-31:2007 “Pipelines pre-insulated with polyurethane foam for hot water supply and heating networks,” which is mandatory for all entities involved in the design, manufacture, and operation of insulated pipelines, no specific type of foaming agent is specified. The standard only establishes a set of physical and mechanical characteristics that the finished insulation must meet.

As part of preparations for the new production facility, UKTRUBOIZOL conducted theoretical and practical research into the selection of foaming agents. The only fundamental requirement of regulatory documents is that polyurethane foam must not contain ozone-depleting substances. This opens up the possibility of using a wide range of modern foaming agents. In industrial practice, the most common blowing agents used in the production of pre-insulated pipes are cyclopentane and n-pentane, as well as carbon dioxide formed as a result of the reaction of isocyanates with water. All of the above groups of blowing agents used in modern effective material systems are suitable for practical application, as they meet the current requirements of international and national standards.

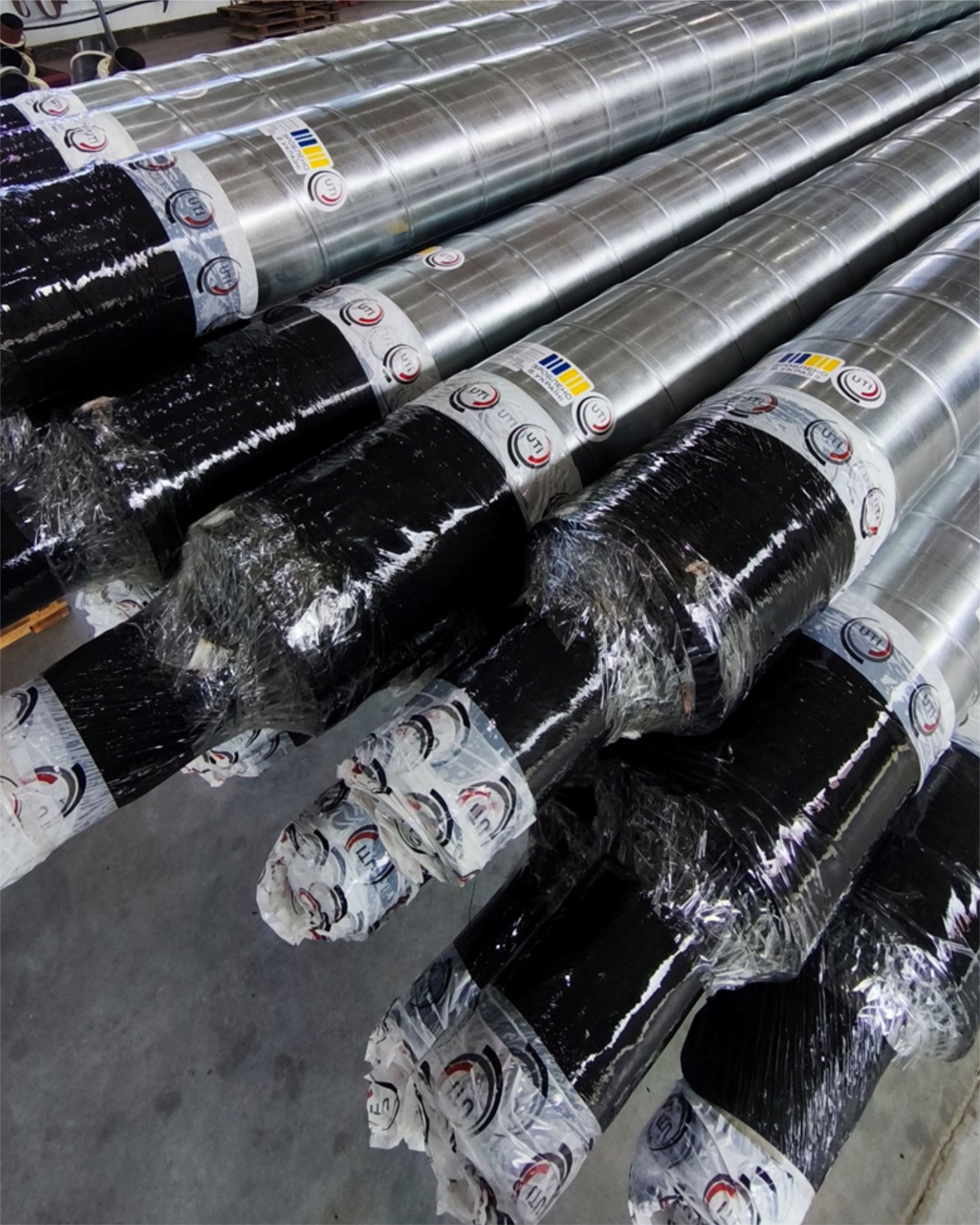

UKRTRUBOIZOL participated in a large-scale delivery of heat-insulated products for the Kharkiv Heat Engineering Systems municipal enterprise, commissioned by the United Nations Office for Project Services (UNOPS). Approximately 30 km of heat-insulated pipes with diameters ranging from 108 to 325 mm and over 2,000 corresponding fittings were manufactured and delivered.

The customer put forward a set of additional requirements for the products in terms of identification, marking, packaging, pipe surface treatment, etc. It should be noted that, in accordance with the customer’s requirements, the manufacturer itself selected the optimal foaming agent for thermal insulation or a combination thereof, focusing on the balance of thermal characteristics, environmental safety, and economic feasibility.

The capabilities of modern equipment and production integration, as well as the research conducted, allowed UKRTRUBOIZOL to fully meet all of the customer’s requirements.