New corrosion protection systems in Ukraine: DENSOLEN® from DENSO Group Germany

LLC NVP with II “Ukrtruboizol”, the official dealer of the German manufacturer of insulation materials DENSO Group Germany, together with representatives of the Ukrainian GTS Operator and JSC “Ukrtransgaz” conducted certification tests of two cold-applied tape systems – DENSOLEN® -AS50 and DENSOLEN® N60/S20.

The goal is to include these materials in the Register of Insulation Materials and Protective Coatings Approved for Use on Gas Transmission System Facilities in Ukraine.

Certification and testing

The process of entering the Register involves several stages:

Previously, Ukrtruboizol had already certified DEKOTEC®-HTS70 heat-shrinkable sleeves for protecting pipe joints, which were entered in the Register for compliance with the DSTU 4219-2003 standard.

This time, the company certified materials that protect not only joints but also the linear part of pipelines.

What was unusual was that the tapes were tested in field conditions at the Ukrainian Gas Transmission System Operator facility, thus bringing the installation conditions closer to real-life operations. Despite difficult weather conditions, including rain, wind, and dust, the test results showed high physical and mechanical properties in terms of adhesion, dielectric integrity, etc., significantly exceeding the requirements of DSTU 4219.

In addition, NVP LLC with II UKRTRUBOIZOL, together with representatives of JSC Ukrtransgaz – Operator of Gas Storage Facilities of Ukraine, conducted the application and successful testing of DENSOLEN tapes for compliance with the DSTU 4219 standard at their own production site.

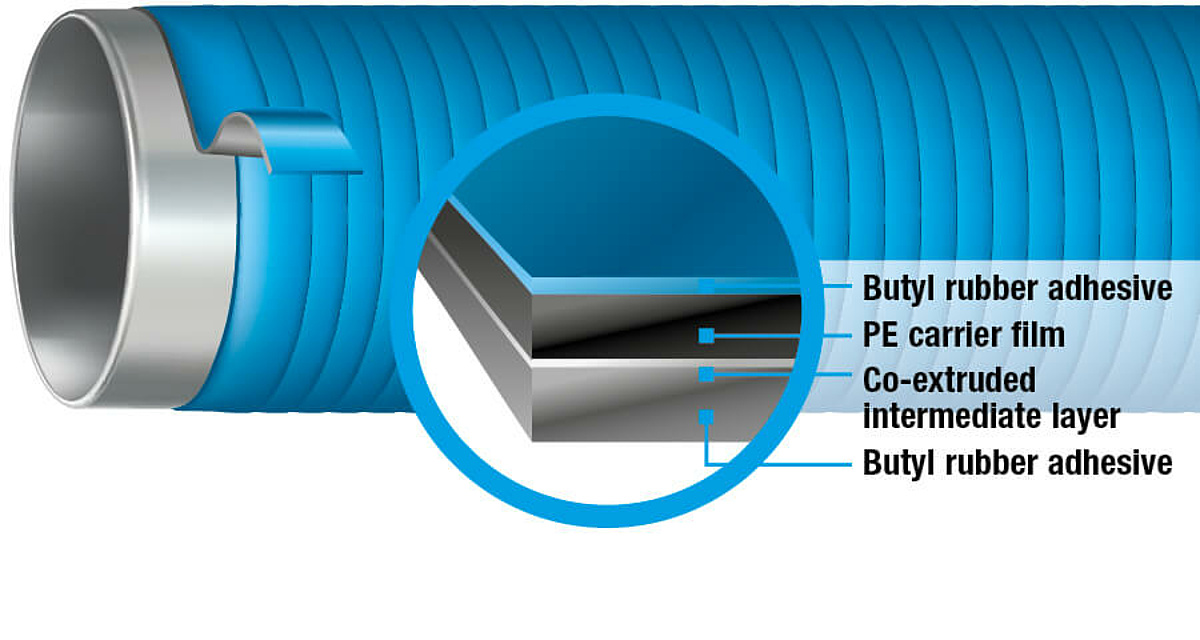

DENSOLEN systems are co-extruded 3-layer synthetic tapes with a stabilized PE carrier film with butyl rubber adhesive on both sides, an inner layer, and an outer adhesive layer. Thanks to the innovative formula of this design, all tape layers of the system are completely fused together.

For optimum adhesion between DENSOLEN® tapes and the pipe surface and factory coating, DENSOLEN®-HT Primer based on ligroin (gasoline) is used as a solvent containing butyl rubber, as well as resins for optimum adhesion.

DENSOLEN®-AS50

Single-strip system, provides excellent protection against corrosion of metal pipes and pipelines in accordance with DIN 30672 and EN12068 standards.

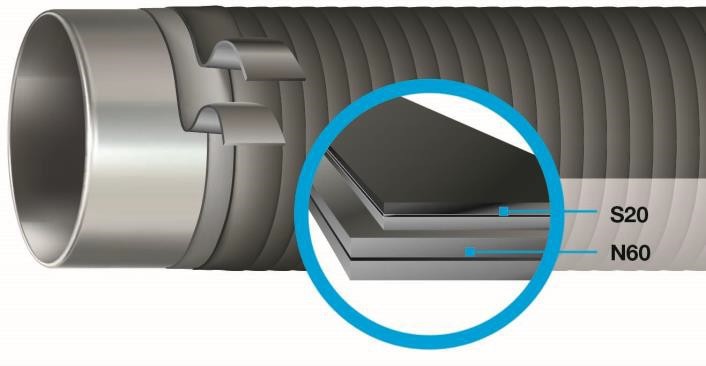

DENSOLEN®-N60/S20

Two-component system for corrosion protection of metal pipes and pipelines in accordance with DIN 30672 and EN12068.

Both systems are compatible with factory coatings made of PE, PP, NEP, PU, bitumen enamel, and bitumen. When using the DENSOLEN system, they are virtually impermeable to water vapor and oxygen and resistant to soil bacteria and electrolytes.

Внесення до Реєстру

Based on the results of joint commission tests conducted by the Ukrainian gas transmission system operator, JSC Ukrtransgaz, and LLC NVP with II UKRTRUBOIZOL, DENSOLEN® -AS50 and DENSOLEN® N60/S20 tapes manufactured by Denso GmbH, together with the single-component epoxy primer DENSOLEN®-HT Primer, have been included in the Register of Insulation Materials and Protective Coatings Based Thereon Approved for Use at Gas Transmission System Facilities in Ukraine (see items 32 and 33 of the Register of Insulation Materials and Protective Coatings Based Thereon Approved for Use at Facilities of the Gas Transmission System of Ukraine) and JSC Ukrtransgaz (see items 33 and item 34 of the Register of Insulation Materials and Protective Coatings Based Thereon Permitted for Use at Facilities of JSC Ukrtransgaz).

DENSO Group Germany – over 100 years of innovation

For 100 years, DENSO Group Germany has been synonymous with high-quality manufacturing processes and outstanding quality in the field of corrosion protection. During this time, DENSO has become one of the leading companies in corrosion prevention solutions for pipelines, as well as sealing technologies for roads and construction sites.

Just a few years after its founding, DENSO Group Germany revolutionized corrosion protection worldwide with the invention of DENSO® Tape (petrolatum tape), known as the first reliable passive corrosion protection for pipelines.

For almost 100 years, this group has been a symbol of high-level manufacturing processes and unmatched product quality. Research, development, and production take place exclusively in Germany. It has its own branches in six European countries.

The group’s core business consists of the production of genuine co-extruded 3-layer polyethylene/butyl tapes, heat-shrinkable sleeves, collars, polyurethane coatings, and bitumen profiles.

The history of the DENSO Group has been marked by many milestones and inventions, resulting in new products and technologies for corrosion protection and road construction. To this day, DENSO-Binde is used as a synonym for petrolatum tapes, and TOK®-Band for bitumen joint tapes. DENSO Group has set many standards in the industry for corrosion protection of pipelines, safe energy transmission, and wear-resistant road surfaces. DEKOTEC® heat-shrinkable sleeves and collars and DENSOLEN® tapes guarantee excellent corrosion protection.

DENSO products are used worldwide in numerous pipeline rehabilitation and new construction projects.

UKRTRUBOIZOL – official representative of DENSO in Ukraine

UKRTRUBOIZOL is a leading pipe center that provides comprehensive solutions in the field of production, supply, and insulation of pipe products. Founded on August 27, 2000, in the city of Dnipro, the company has grown from a specialized manufacturer to a leader in the field of anti-corrosion insulation of steel pipes (Ø25 – Ø1420 mm).

Today, UKRTRUBIZOL is a company with a full cycle of pipe production, including manufacturing, processing, insulation, and supply of pipe products for engineering networks, energy, construction, and industry.

UKRTRUBIZOL is more than just a pipe manufacturer. It is a single pipe center where customers receive a full range of services: